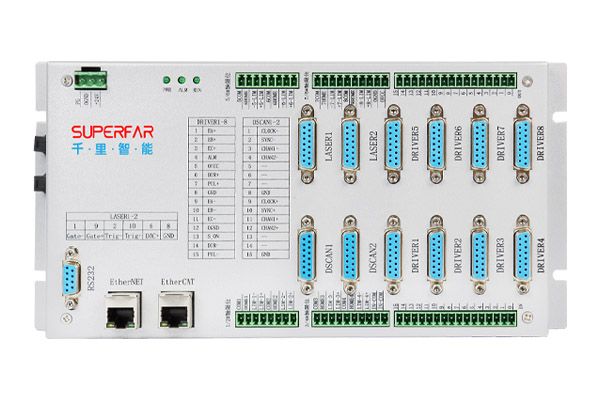

QLS-821 8 Axis Galvo Platform Linkage Control Card

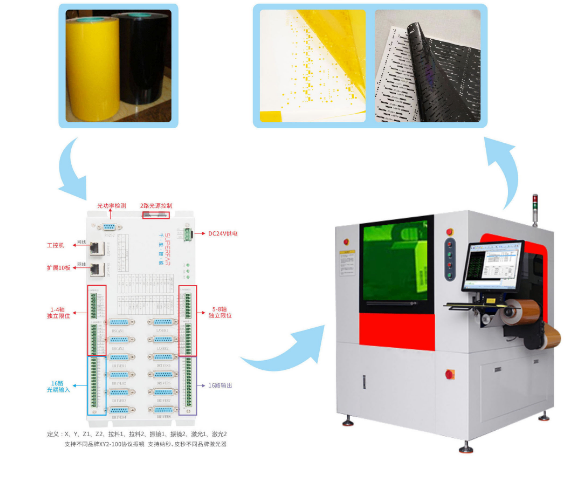

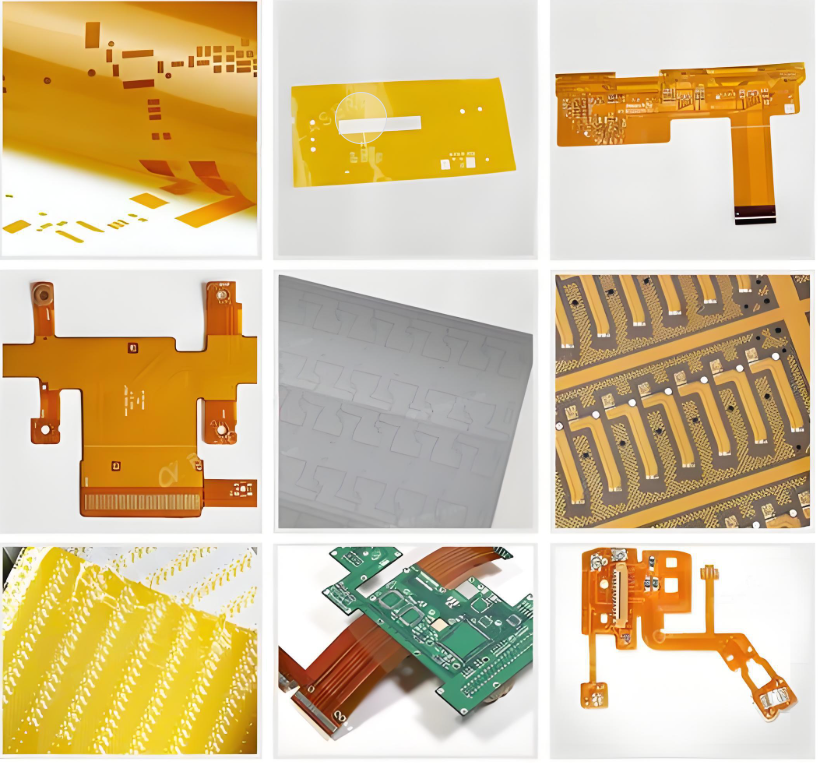

QLS-821 8 Axis Galvo Platform Linkage Control Card supports eight axis plus a single galvanometer and single laser control. Its dual galvanometers can operate synchronously or asynchronously and can control stepper/servo/linear motors. With an improved S-curve acceleration/deceleration algorithm and look-ahead control, the machine achieves faster and smoother speed transitions, enabling high-precision, high-efficiency, and large-format processing. It is currently widely used in industries such as PCB and FPCB, including processes like FPC cover film roll-to-sheet, FPC cover film roll-to-roll, FPC outline cutting, FPC flexible boards, cover films, PET films, PI films, PP films, adhesive films, copper foil, explosion-proof films, electromagnetic films, and various other thin-film and circuit board auxiliary materials. It also supports FPC outline cutting functionality.

Application:

Category | Description |

Control Features | - Achieves 8 axis synchronization between platform movement and galvanometer scanning - Integrates motor axis motion and galvanometer control into a unified system, Simplifies equipment integration - Reduces costs while enhancing performance. |

Computational Performance | - Equipped with a high-performance digital processing unit (QLS-821 platforms) - Ultra-short servo cycles for high-speed precision control. |

Communication Capabilities | - EtherNET 1000M Ethernet communication - Independent operating system |

EtherCAT Interface | - Simplified wiring, exceptional scalability, anti-interference performance |

Data Storage | - Large-capacity memory architecture supporting high-speed data throughput applications |

Core Features | - Supports 8 axis and single galvanometer and dual/single laser - Dual galvanometer enables synchronous or asynchronous processing - Compatible with stepper/servo/linear motors - Enhanced S-curve acceleration/deceleration and look-ahead control for machine stability- Vector and bitmap processing - XY2-10 protocol and 16-bit resolution control signals - 5V TTL Gate/Trigger laser signal synchronization - Fully independent intellectual property, perfect Galvo control solutions. |

| Application | FPC/PCB cutting, Mobile camera module cutting,Fingerprint recognition module cutting,Memory card & TF card cutting,ITO film etching,Large-format marking,FPC cover film roll-to-piece and roll-to-roll cutting |