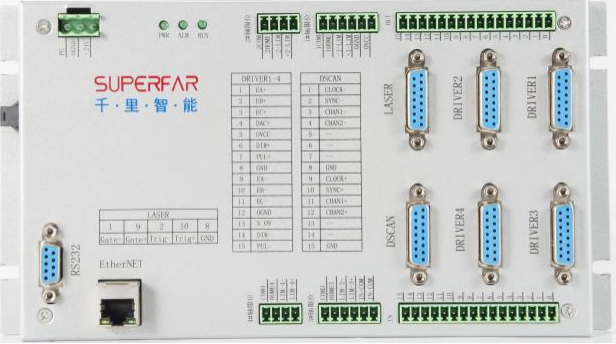

4 Axis Galvo Platform Linkage Control Card QLS-421

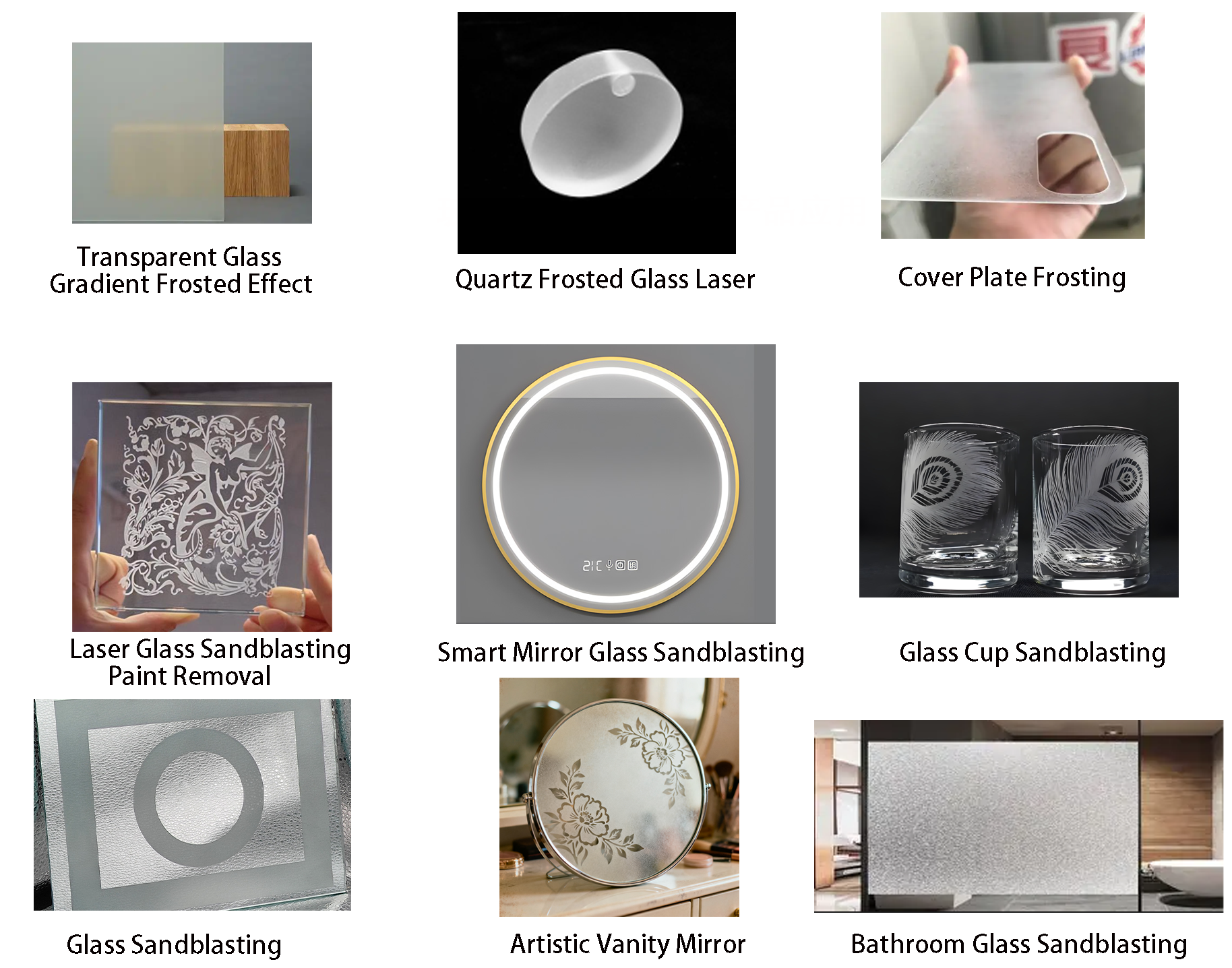

QLS-421 4 axis platform galvanometer linkage card, enables synchronized galvanometer scanning and platform movement. This integration delivers high precision, high efficiency, and large-format processing capabilities. The solution reduces equipment costs, enhances machine performance, and simplifies system integration, making it an ideal solution for laser glass sandblasting, mirror polishing, and paint removal equipment.

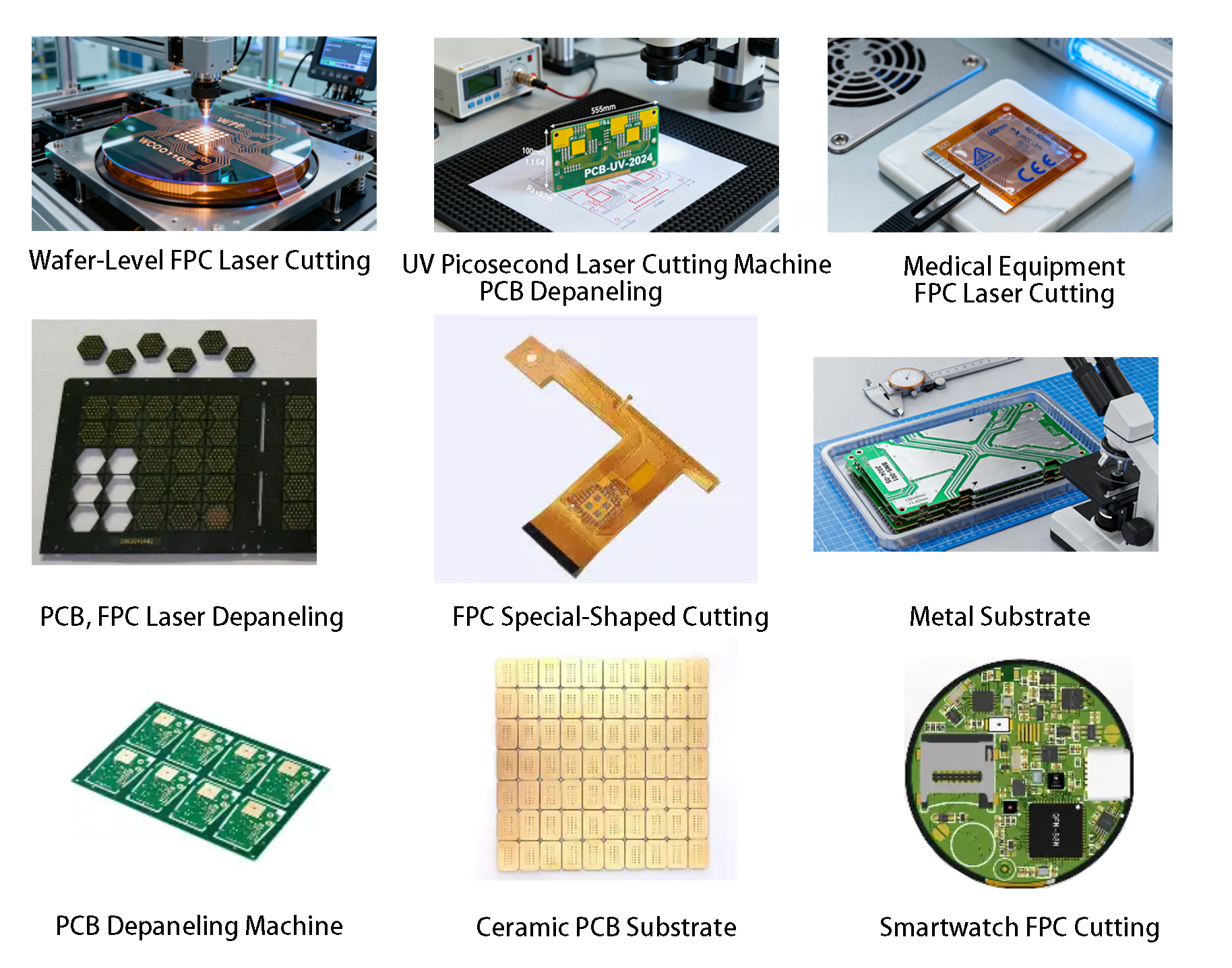

Application:

Category | Description |

Control Features | - Achieves 3-axis/4-axis synchronization between platform movement and galvanometer scanning - Integrates motor axis motion and galvanometer control into a unified system, Simplifies equipment integration - Reduces costs while enhancing performance. |

Computational Performance | - Equipped with a high-performance digital processing unit (QLS-421/421(3D) & QLS-422 platforms) - Ultra-short servo cycles for high-speed precision control. |

Communication Capabilities | - EtherNET 1000M Ethernet communication - Independent operating system |

EtherCAT Interface | - Simplified wiring, exceptional scalability, anti-interference performance |

Data Storage | - Large-capacity memory architecture supporting high-speed data throughput applications |

Core Features | - Supports 4axis and dual/single galvanometer and dual/single laser - Dual galvanometer enables synchronous or asynchronous processing - Compatible with stepper/servo/linear motors - Enhanced S-curve acceleration/deceleration and look-ahead control for machine stability- Vector and bitmap processing - XY2-10 protocol and 16-bit resolution control signals - 5V TTL Gate/Trigger laser signal synchronization - Fully independent intellectual property, perfect Galvo control solutions. |

Application | Glass sandblasting, mirror paint removal, glass drilling for Quartz glass, clear glass, blue glass, K9 glass, sapphire, colored glass and other application |