QLMark Laser Marking Control System

Application

Laser marking usage for QR code anti-counterfeiting, PCB/diamond marking, 3D surface/on-the-fly marking, 3D printing, CO₂ laser applications, fiber laser applications, solid-state laser applications, and other laser marking uses.

System Overview

SuperFar Intelligent QLMark marking software, in conjunction with the QLS-221/221FLY/221(3D) marking card, supports the XYZ-100 data transfer protocol. The marking card communicates with the galvanometer scanning system through a 16-bit resolution control signal, enabling the processing of vector graphics and bitmap images. This system is applied to automated marking equipment. A single computer can control dozens of marking machines simultaneously, thus reducing costs.

System Architecture

The QLS-221/221(FLY)/221(3D) marking card and the QLM-241 integrated marking card, based on a Linux operating system, feature a control platform with a digital processing unit. Equipped with a 1000M Ethernet interface, the system ensures high-speed and stable communication. It uses a multi-core CPU for computing, offering high precision and excellent cutting and marking performance.

Software

QLMark Marking software

Advantage

Technical Module | Innovation Design Highlights |

All in One | QLM-241 features a built-in LINUX operating system, eliminating the need for a computer and reducing costs |

Fly Marking | Enables dynamic processing during motion, improving marking efficiency |

Infinite working range | Combines platform and galvanometer coordination for seamless processing without splicing marks, offering unrestricted machining area |

Universal Control | Supports CO₂ lasers, fiber lasers, and solid-state lasers |

Control Features | Compatible with vector and bitmap processing, synchronized laser scanning output, and repeatable precision machining |

Visual Position | Utilizes visual positioning for accurate processing and automatic galvanometer calibration |

Secondary Development | Allows customization and provides SDK and tailored solutions for industry-specific needs |

Hardware

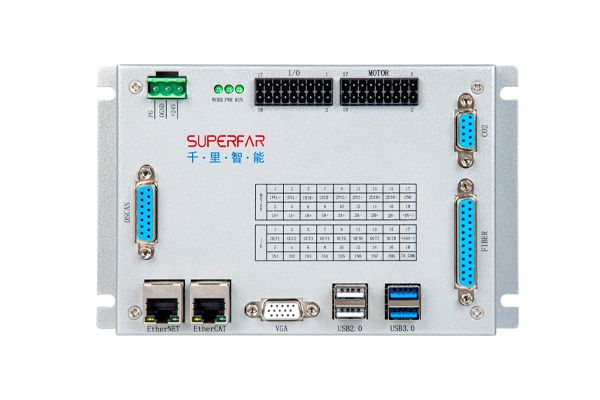

Network Marking control card

QLS-221/221(FLY)/221(3D) QLM-241

Category | Description |

Operating System | QLM-241 marking card features a built-in Linux OS, eliminating the need for an external computer and reducing costs. |

Control Features | • Supports XYZ-100 data transmission protocol |

Computational Performance | • Equipped with high-performance digital processing unit |

Communication Capabilities | • Dual 1000M Ethernet interface design (EtherNET), driver-free |

Core Strengths | • Cost-effective: No computer required, reduces equipment investment |

Hardware Interfaces | • Two-channel encoder input + two-axis pulse/direction output |

Application | QR code anti-counterfeiting, PCB/diamond marking, 3D surface/on-the-fly marking, 3D printing, CO₂ laser applications, fiber laser applications, solid-state laser applications, and other laser marking uses. |

About Us

Shenzhen SuperFar Intelligent Control Technology Co., Ltd

Step by step, the miles are gained; Floor by floor, the view's obtained.

SuperFar located in Shenzhen, has a core competitive technical team dedicated to the development and sales of high-end motion controllers, mirror systems, servo drives, robot control systems, and customized software systems.

After years of dedicated research and development and customer use, continuous testing and improvement, the independently developed high-end motion controller and supporting control software have won full recognition and affirmation from customers with stable performance, fast speed, high precision, strong functionality, and convenient use, greatly enhancing the competitiveness of customer equipment in terms of performance price ratio. SuperFar has steadily moved towards becoming the first high-tech company in China to develop high-end multi-dimensional motion controllers.

SuperFar's series of products are widely used in industrial control fields such as laser processing equipment (marking, cutting, welding, drilling, surface modification, 3D printing, etc.), electronic industry application equipment (processing, testing), production automation equipment, CNC machine tools, printing machinery, special machine tools, robots, packaging machinery, clothing processing machinery, etc.

SuperFar continues to invest in research and development, and new series of products will be continuously introduced to the market to enhance customer competitiveness and work together with customers to create brilliance.

Certificate

Customer

Exhibition

After sale service

1. 7*24 hours online support

2. Professional after sales team support and guide

3. Powerful R&D team capable of ODM/OEM service and secondary development requirements

FAQ

Q: Can the software support secondary development?

A: We provide SDK packages to facilitate customer secondary development.

Q: What is the product warranty period?

A: Boards come with a one-year warranty, including free repair services.

Q: Can you provide on-site installation and debugging?

A: Our dedicated after-sales team assists with on-site installation and debugging.

Q: What are the main applications of this laser marking system?

A: The QLMark laser marking system is widely use with QR code anti-counterfeiting, PCB/diamond marking, 3D surface/on-the-fly marking, 3D printing, CO₂ laser applications, fiber laser applications, solid-state laser applications, and other laser marking usage.