QLS-221 Network Laser Marking Control Card

QLS-221/221FLY/221(3D) marking card, supports the XYZ-100 data transfer protocol. The marking card communicates with the galvanometer scanning system through a 16-bit resolution control signal, enabling the processing of vector graphics and bitmap images. This system is applied to automated marking equipment. A single computer can control dozens of marking machines simultaneously, thus reducing costs.

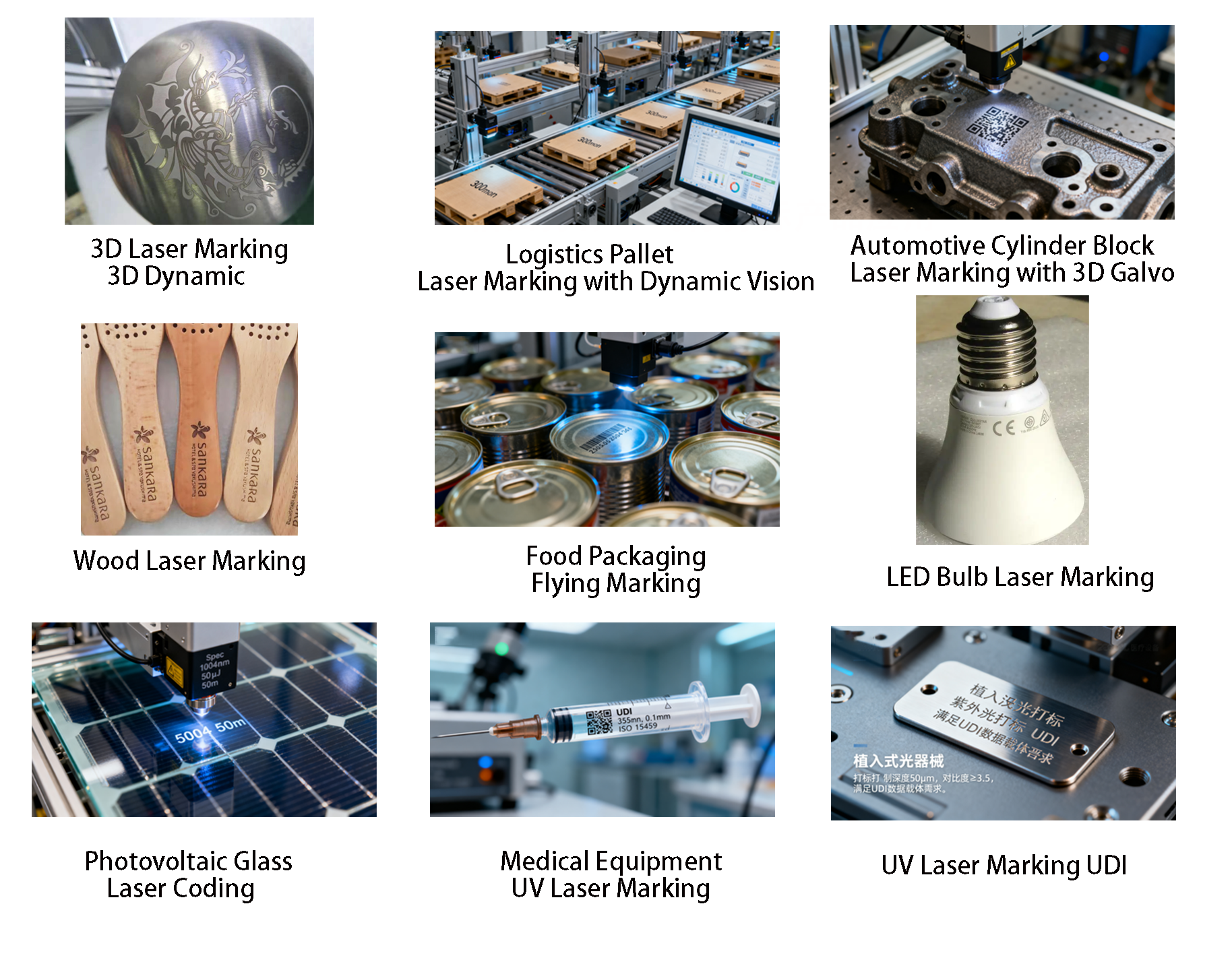

Application

Category | Description |

Operating System | Windows Operate system with PC. |

Control Features | • Supports XYZ-100 data transmission protocol |

Computational Performance | • Equipped with high-performance digital processing unit |

Communication Capabilities | • Dual 1000M Ethernet interface design (EtherNET), driver-free |

Core Strengths | • Cost-effective: No computer required, reduces equipment investment |

Hardware Interfaces | • Two-channel encoder input + two-axis pulse/direction output |

Application | QR code anti-counterfeiting, PCB/diamond marking, 3D surface/on-the-fly marking, 3D printing, CO₂ laser applications, fiber laser applications, solid-state laser applications, and other laser marking uses. |