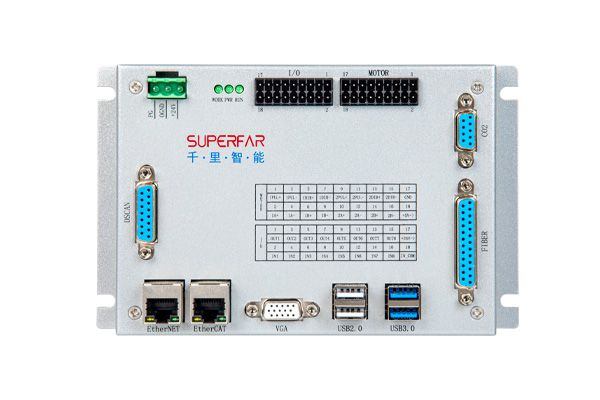

QLM-241 Network Laser Marking Control Card

QLM-241 integrated marking card, based on a Linux operating system, feature a control platform with a digital processing unit. Equipped with a 1000M Ethernet interface, the system ensures high-speed and stable communication. It uses a multi-core CPU for computing, offering high precision and excellent cutting and marking performance.

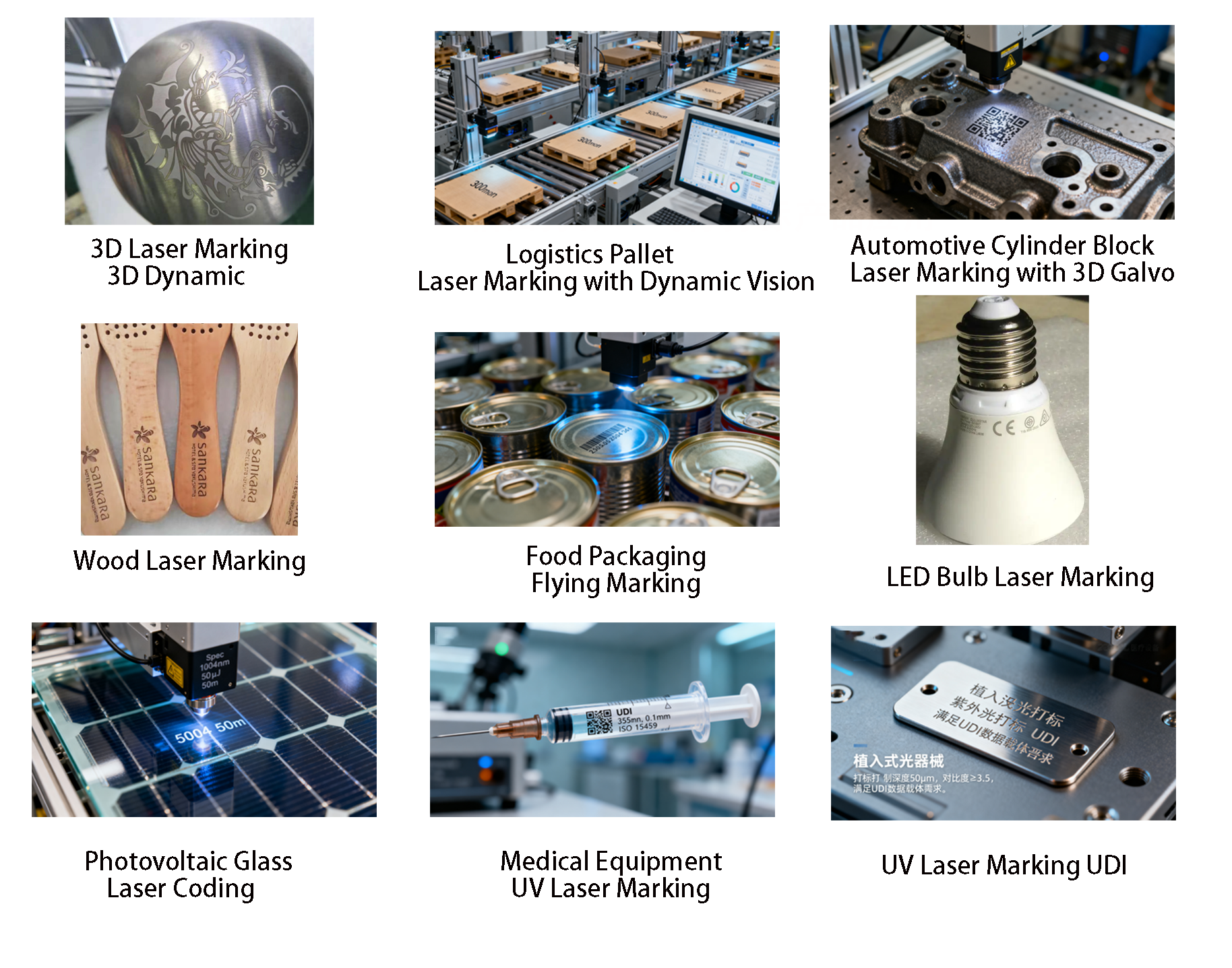

Application

Category | Description |

Operating System | QLM-241 marking card features a built-in Linux OS, eliminating the need for an external computer and reducing costs. |

Control Features | • Supports XYZ-100 data transmission protocol |

Computational Performance | • Equipped with high-performance digital processing unit |

Communication Capabilities | • Dual 1000M Ethernet interface design (EtherNET), driver-free |

Core Strengths | • Cost-effective: No computer required, reduces equipment investment |

Hardware Interfaces | • Two-channel encoder input + two-axis pulse/direction output |

Application | QR code anti-counterfeiting, PCB/diamond marking, 3D surface/Fly marking, 3D printing, CO₂ laser applications, fiber laser applications, solid-state laser applications, and other laser marking uses. |