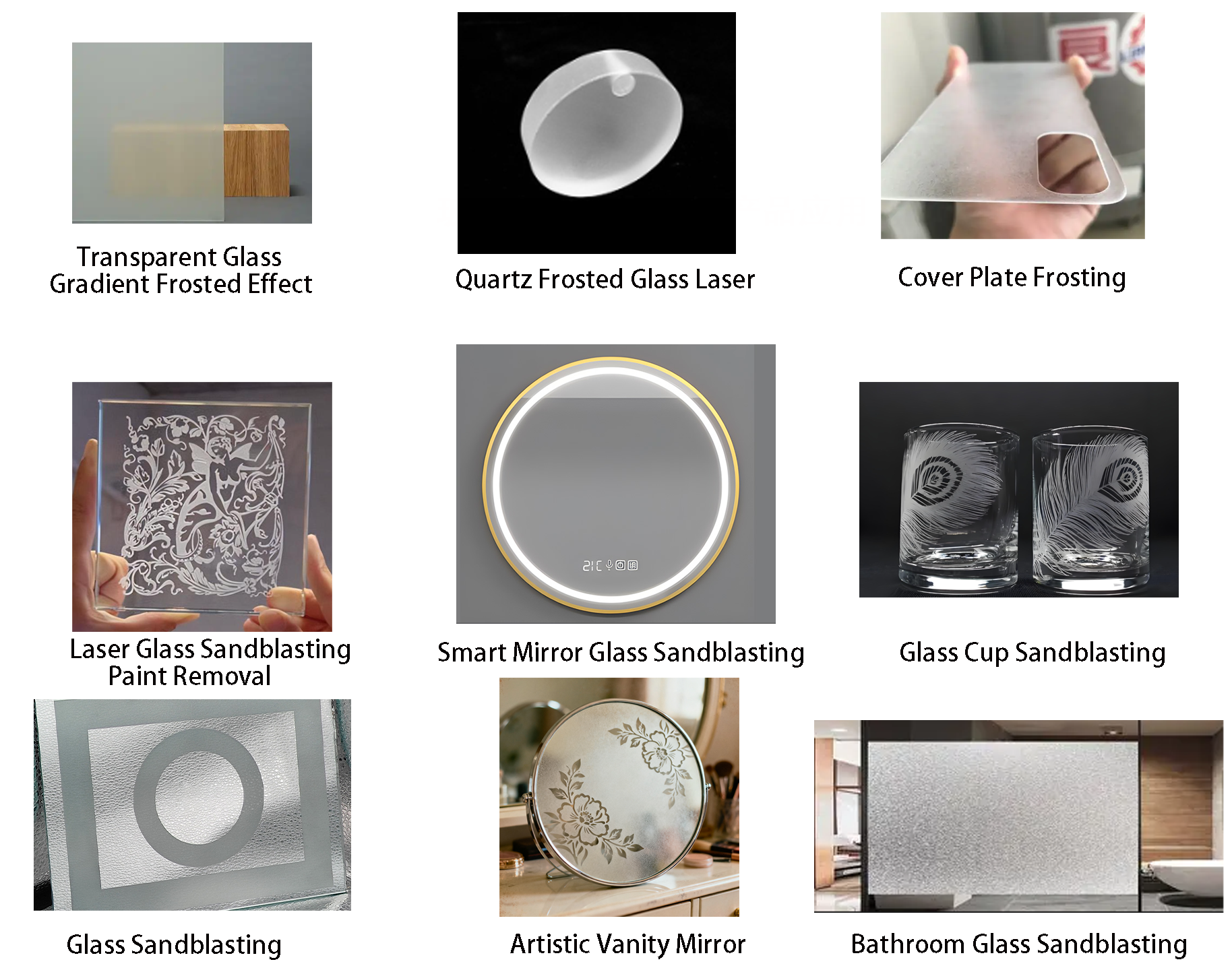

Application

System Overview

SuperFar offers a comprehensive laser glass sandblasting, mirror paint removal, and drilling system. By deeply integrating four axis high precision motion control with enhanced S curve acceleration/deceleration algorithms and look-ahead control, the system optimizes performance and provides built-in multiple filling pattern options. It consolidates multiple glass processing workflows such as glass sandblasting, mirror paint removal, and glass drilling into a single integrated solution.

The galvanometer axis synchronized motion system effectively solves large format production stitching challenges. While excelling in smart mirror manufacturing, the system is also widely applied across diverse glass materials—including float glass, optical glass, micro crystalline glass, soda-lime glass, architectural glass, and high borosilicate glass for precision drilling, frosting, coating stripping, and marking. This versatility ensures high performance processing for a broad range of material applications.

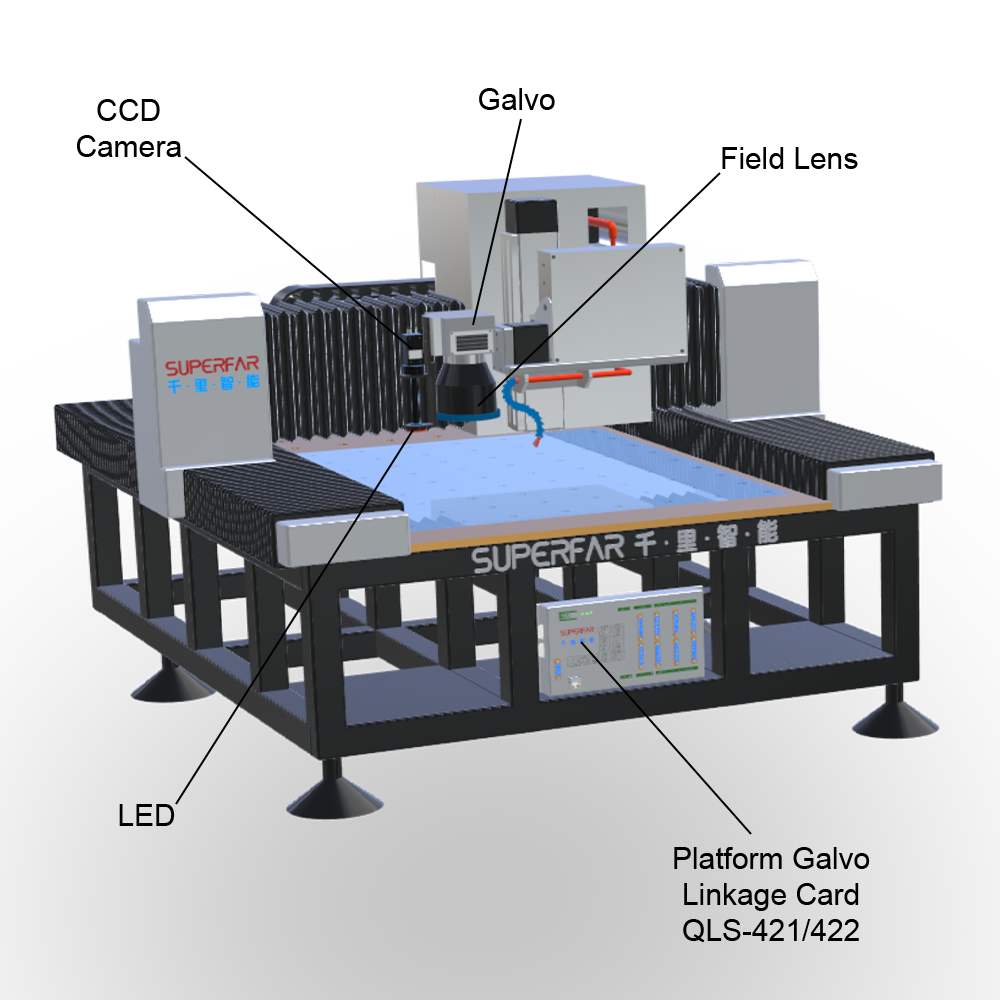

System Architecture

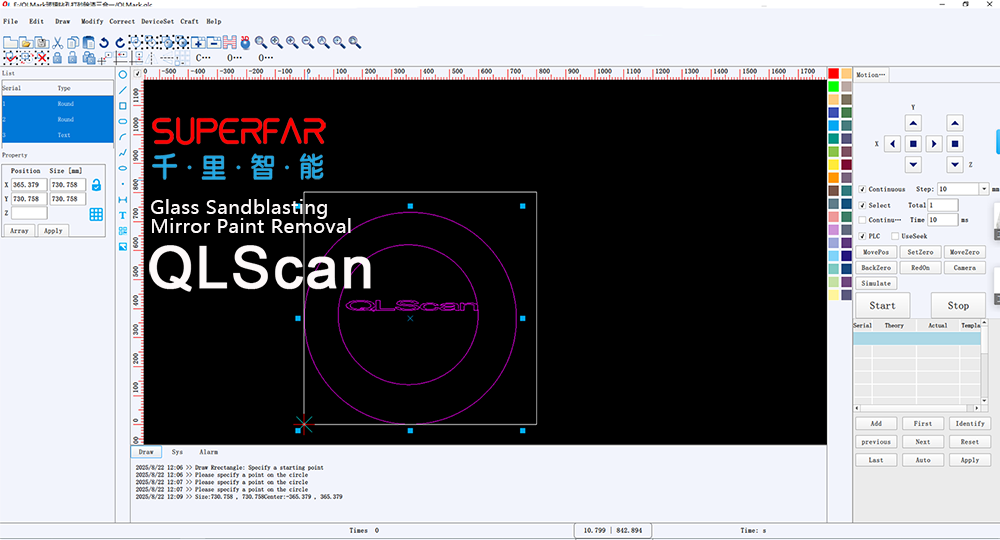

QLScan software, paired with the QLS-421/422 four axis platform galvanometer linkage card, enables synchronized galvanometer scanning and platform movement. This integration delivers high precision, high efficiency, and large-format processing capabilities. The solution reduces equipment costs, enhances machine performance, and simplifies system integration, making it an ideal solution for laser glass sandblasting, mirror polishing, and paint removal equipment.

Software

QLScan Glass Sandblasting Mirror Paint Removal software

Advantage

Technical Module | Innovation Design Highlights |

Integrated Motion Control | Achieves 3 axis/4 axis synchronization between platform movement and galvanometer scanning, enhancing processing efficiency |

Quality Assurance | Minimizes glass chipping, eliminates burrs, and ensures zero taper for clean, precise holes. |

Adaptive Processing | Capable of drilling on uneven glass materials (e.g., pipes, curved surfaces) without direct contact |

Micro-Hole Drilling | Precisely creates holes ranging from 0.1–0.8 mm with high accuracy |

Variable Thickness Support | Z axis focus adjustment accommodates glass and mirrors of varying thicknesses. |

Irregular-Shaped Hole Drilling | Programmable laser path control enables easy processing of complex shapes (e.g., pentagrams). |

Visual Positioning | Vision-assisted alignment ensures precision, while galvanometer calibration becomes more streamlined. |

Stable, Efficient & Eco-Friendly | Ensures stable output power, user-friendly operation, and zero consumables or pollution, significantly reducing enterprise operational costs. |

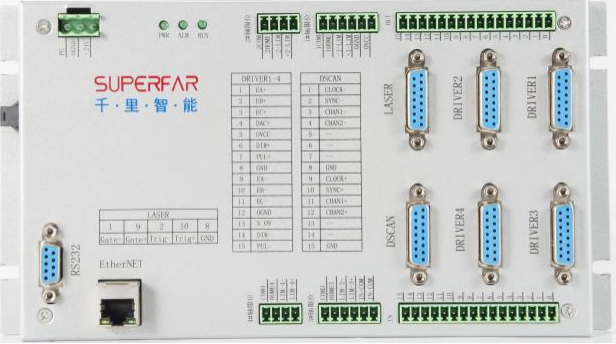

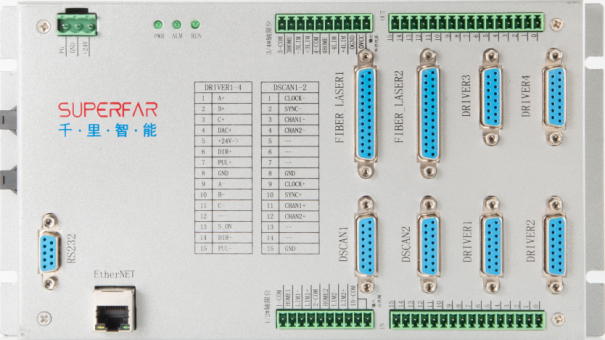

Platform Galvo Linkage controller QLS-421/422

Category | Description |

Control Features | - Achieves 3-axis/4-axis synchronization between platform movement and galvanometer scanning - Integrates motor axis motion and galvanometer control into a unified system - Simplifies equipment integration - Reduces costs while enhancing performance. |

Computational Performance | - Equipped with a high-performance digital processing unit (QLS-421/421(3D) & QLS-422 platforms) - Ultra-short servo cycles for high-speed, high-precision control. |

Communication Capabilities | - EtherNET 1000M Ethernet communication without driver dependencies |

EtherCAT Interface | - Simplified wiring, exceptional scalability, and robust anti-interference performance |

Data Storage | - Large-capacity memory architecture supporting high-speed data throughput applications |

Core Features | - Supports 4axis and dual/single galvanometer and dual/single laser - Dual galvanometer enables synchronous or asynchronous processing - Compatible with stepper/servo/linear motors - Enhanced S-curve acceleration/deceleration and look-ahead control for machine stability - XY2-10 protocol and 16-bit resolution control signals - Vector and bitmap processing - 5V TTL Gate/Trigger laser signal synchronization - Fully independent intellectual property, perfect galvanometer control solutions. |

Application | - PCB/FPC cutting, fingerprint recognition chip processing - Precision laser cutting for camera modules - Large-format marking, wafer scribing & slot marking, seamless stitching - 3D printing, glass drilling, mirror paint removal, glass sandblasting. |

About Us

Shenzhen SuperFar Intelligent Control Technology Co., Ltd

Step by step, the miles are gained; Floor by floor, the view's obtained.

SuperFar located in Shenzhen, has a core competitive technical team dedicated to the development and sales of high-end motion controllers, mirror systems, servo drives, robot control systems, and customized software systems.

After years of dedicated research and development and customer use, continuous testing and improvement, the independently developed high-end motion controller and supporting control software have won full recognition and affirmation from customers with stable performance, fast speed, high precision, strong functionality, and convenient use, greatly enhancing the competitiveness of customer equipment in terms of performance price ratio. SuperFar has steadily moved towards becoming the first high-tech company in China to develop high-end multi-dimensional motion controllers.

SuperFar's series of products are widely used in industrial control fields such as laser processing equipment (marking, cutting, welding, drilling, surface modification, 3D printing, etc.), electronic industry application equipment (processing, testing), production automation equipment, CNC machine tools, printing machinery, special machine tools, robots, packaging machinery, clothing processing machinery, etc.

SuperFar continues to invest in research and development, and new series of products will be continuously introduced to the market to enhance customer competitiveness and work together with customers to create brilliance.

Certificate

Customer

Exhibition

After sale service

1. 7*24 hours online support

2. Professional after sales team support and guide

3. Powerful R&D team capable of ODM/OEM service and secondary development requirements

FAQ

Q: Can the software support secondary development?

A: We provide SDK packages to facilitate customer secondary development.

Q: What is the product warranty period?

A: Boards come with a one-year warranty, including free repair services.

Q: Can you provide on-site installation and debugging?

A: Our dedicated after-sales team assists with on-site installation and debugging.

Q: What are the main applications of this control system?

A: The QLMark laser glass drilling control system is use for Glass drilling for Glass Back Panels, Glass Cabinets, Glass Cover Plates, Glass Curtain Walls, Optical Glass, HUD Glass, and Smart Mirror Glass and other glass drilling application