QLC-420(CUT) 4 Axis Sheet Metal Cutting Control Card

QLC-420(CUT) 4 Axis Sheet Metal Cutting Control Card4-axis pulse/direction and EtherCAT bus control, and integrates an analog fully-closed-loop height control axis. This enables a single card to control all machine motion and height adjustment, delivering a high-precision, high-efficiency laser sheet metal cutting solution.

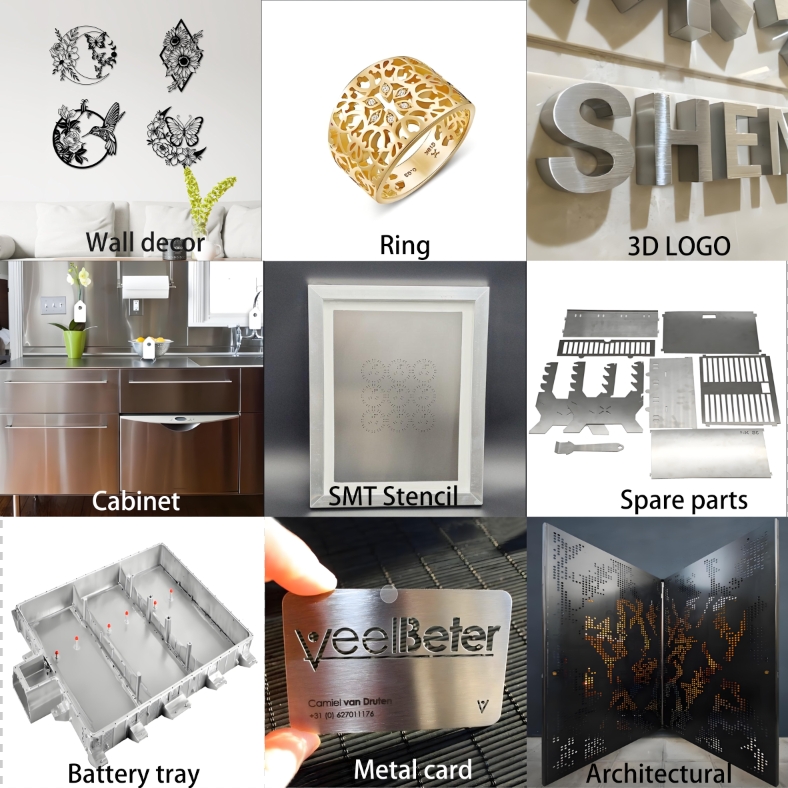

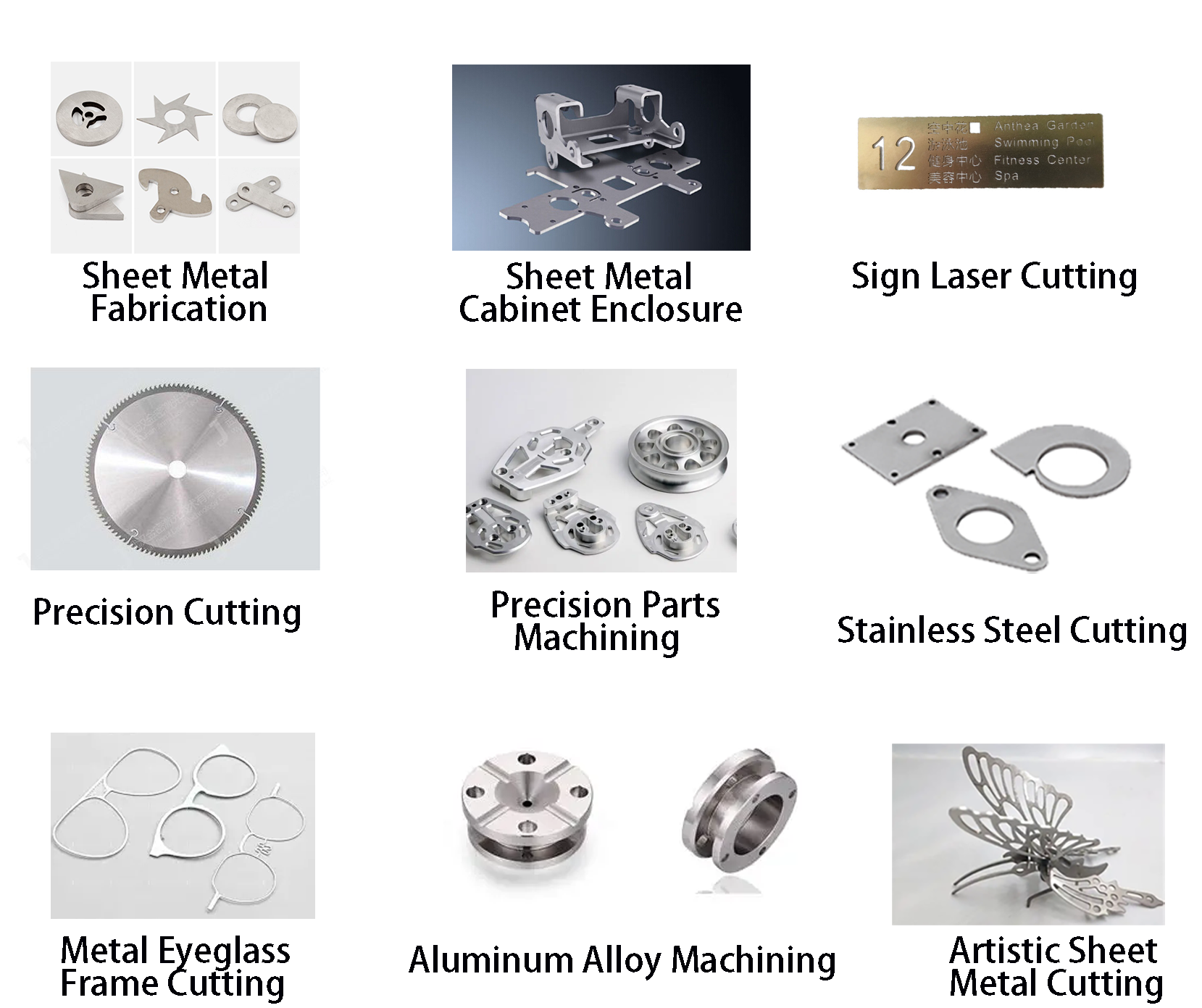

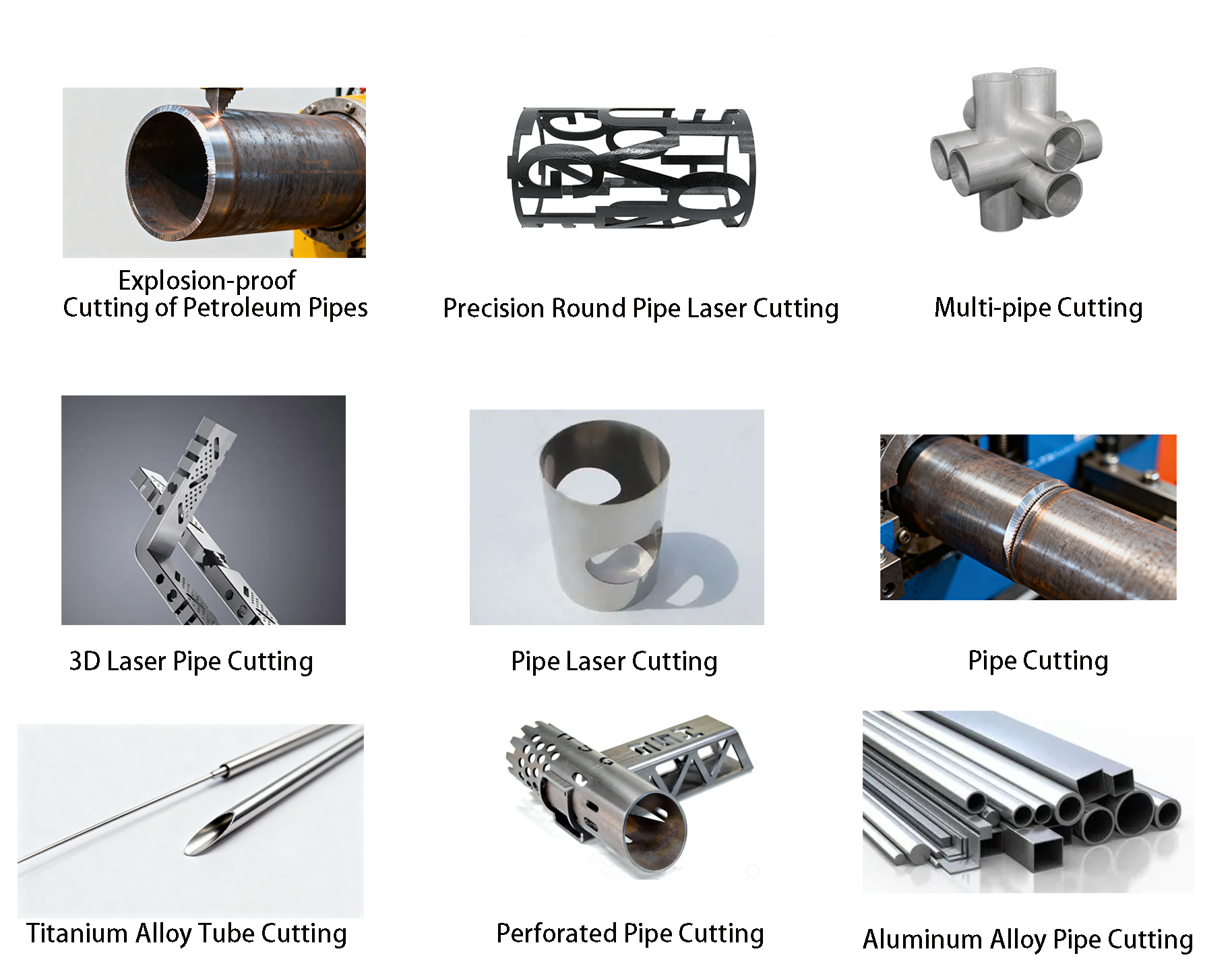

Application:

Stainless steel, carbon steel, cold-rolled sheets, galvanized sheets, copper materials, aluminum substrates, and other metal laser processing applications.

Category | Description |

Control Features | - Supports 4-axis pulse/direction and EtherCAT bus control - Excellent anti-interference capability with independent encoder filtering for each axis - 1ms control cycle with filtered S-curve acceleration/deceleration, look-ahead, and corner optimization algorithms |

Computing Performance | - QLC-420cut platform equipped with high-performance digital processing unit. - Ultra-short servo cycle suitable for high-speed, high-precision scenarios |

Communication Capabilities | - EtherNET 1000M Ethernet communication - Independent operating system |

EtherCAT Interface | - Simplified wiring, exceptional scalability, and robust anti-interference performance |

Data Storage | - Large-capacity memory architecture supporting high-speed data throughput applications - Four-channel encoder input + four-axis pulse output -Two-channel ±10V DAC analog output. -24-output/27-input IO, support customized option |

Application | Stainless steel, carbon steel, cold-rolled sheets, galvanized sheets, copper materials, aluminum substrates, and other metal laser processing applications. |